We start by analyzing the water you have at-hand to make sure our device are the proper fit for your community and as our device is powered by renewable energy, it can be placed anywhere.

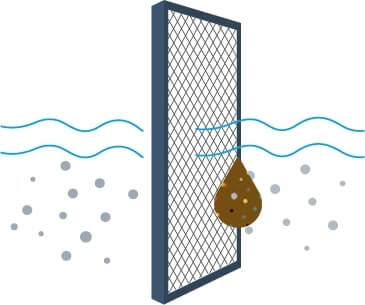

We use microfiltration to separate suspended solids from the raw water in order to prevent damage and clogging in the next membrane purification steps. Also, bacteria are being removed in this step.

Often the origin of the color and smell of the raw water, dissolved organic matters and chlorine get absorbed and removed in the active carbon filter.

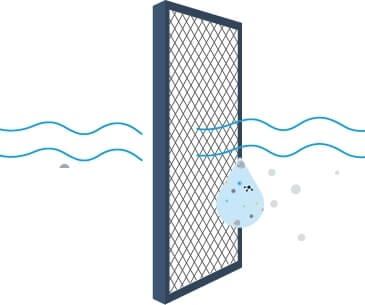

The first membrane purification step is the ultrafiltration (UF) in which remaining suspended solids and colloids are removed, as well as all remaining bacteria and viruses that are still present in the water. When starting from a freshwater source, at this point pure drinking water can already be obtained.

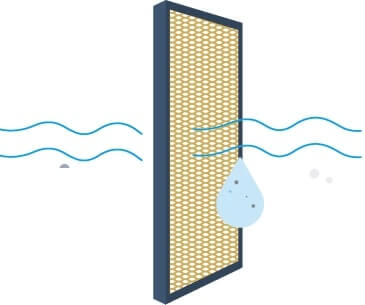

The nanofiltration filter removes heavy metals from the water, softens the water and eliminates remaining dissolved organic compounds as well as pesticides/herbicides.

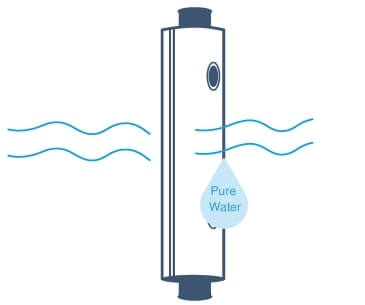

Reverse osmosis (RO) is used to desalinate the entry water, meaning that all ions are removed. This membrane will only be applied for water sources with a degree of salinity above the WHO drinking water limit (600 mg/L).

Depending on the salinity of the water source, high pressures are needed with large corresponding energy consumption. Therefore, in our devices, we focus on maximum energy recovery using the latest robust technologies.

As our devices produce drinking water, the minerals that were removed in the RO membrane purification step need to be replenished to acquire healthy and tasty water. Therefore, after the RO, a remineralization step is added in our device.

Without the use of any chemicals, our device includes an additional disinfection process based on LED-UV, which acts as an additional safety barrier to assure the highest quality of the produced drinking water at all times.

We strongly believe in sustainability, which is why we strongly advise you to use reusable bottles along with our device. We can help in designing one for you.