Membranes are semi-permeable separation media (thin sheets of material) that allow to isolate one substance from another, by selectively letting only the desired one to pass through. The mechanism requires to push the fluid through the membrane pores, so the separation occurs.

In water treatment, membranes are engineered to separate water from contaminants based on properties like particle size or charge[1]. Water passes through, leaving larger particles, microorganisms and other contaminants behind.

When compared to other processes, membranes have the advantage of being a separation method with low energy consumption, contrarily to evaporation or distillation, in which a considerable amount of heat is added to achieve separation.

In general, membrane processes reduce the number of unit operations, and they operate continuously and automatically[2] without necessity of moving parts within the system, except for pumps or compressors, which are necessary to move and push the fluid through the membranes.

Membranes stand as an attractive alternative to conventional wastewater treatment processes, since they do not require the addition of chemicals (only for the cleaning of the membranes), the process is straightforward with simple control schemes and maintenance load [2], and typically has a low footprint.

Nonetheless, just like any other, membrane systems also have some disadvantages, fouling being the main one[2].

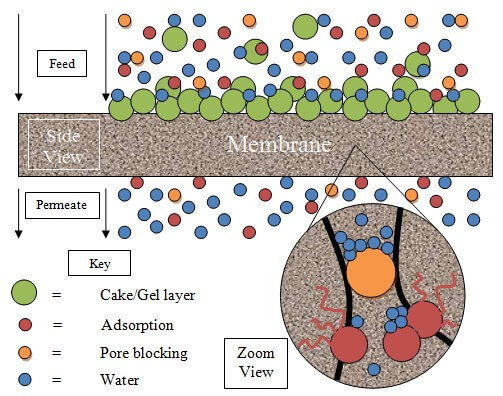

Fouling, or membrane contamination, occurs when suspended or dissolved solids accumulate on the external membrane surface (generating a cake), or on/within the pores (pore plugging or blocking)[3]. Fouling results in higher energy use to push the fluid through, reduction on the permeate (purified substance) flux over time[2], higher cleaning frequency and shorter lifespan of the membrane[3] (a three to six year average membrane lifetime). Pores can get clogged with clay and organic materials if particle rich streams are not pre – filtered[1].

Fouling is one of the major problems that led to the perception of membranes being unreliable and expensive[4], as fouling decreases the permeate flux[2]. However, optimized cleaning cycles have been established to date which are in many cases a combination of physical and chemical cleaning methods. Moreover, membranes processes will always produce two streams as a result, the permeate and the retentate, which is the stream with the remaining contaminants. Retentate, usually requires further treatment prior to disposal as it is in fact a concentrated feed stream[6]. In industry, recovery ratios up to 85% are seen, leaving a very concentrated stream to discharge or use for further resource extraction (zero liquid discharge).

The mentioned disadvantages, however, have not limited the spreading of membrane technology worldwide. Increasing population, growing concerns about contaminants in water, decline in safe clean and easily accessible water sources, the current and forecasted water scarcity[8], along with the large amounts of water industry utilizes[9], are factors driving society and technology towards techniques and practices that allow to count on clean water with minor energy use. Not in vain, membranes currently allocate themselves as a multi-billion dollar industry[8] and stand as a reliable option when it comes to water reuse.

The necessity of transitioning towards a cleaner and more energy efficient world, accompanied by a deployment of industrial and domestic wastewater reuse, pushes membrane technology to elaborate optimization. This yields a reduction of overall lifecycle costs, which unquestionably will make membranes the key technology of future water treatment.

BOSAQ uses membrane technology for its systems. Within the BOSAQ off-grid drinking water production devices, use of chemicals for membrane cleaning is reduced to an absolute minimum by means of smart deployment of innovative ‘green’ fouling prevention methods.

[1] N. Academies, ‘Safe Drinking Water Is Essential’, Reports from the National Academies, 01-Sep-2007. [Online]. Available: https://www.koshland-science-museum.org/water/html/en/Treatment/Membrane-Processes.html. [Accessed: 27-Oct-2018].

[2] W. Guo, H.-H. Ngo, and J. Li, ‘A mini-review on membrane fouling’, Bioresour. Technol., vol. 122, pp. 27–34, Oct. 2012.

[3] ‘Membrane fouling’. [Online]. Available: https://www.lenntech.com/membrane-fouling.htm. [Accessed: 28-Oct-2018].

[4] ‘Exploring membrane technology’, edie.net. [Online]. Available: https://www.edie.net/library/Exploring-membrane-technology/2785. [Accessed: 26-Oct-2018].

[5] ‘The Challenge of Membrane Maintenance’, Water & Wastes Digest. [Online]. Available: https://www.wwdmag.com/membranes-microfiltration/challenge-membrane-maintenance. [Accessed: 27-Oct-2018].

[6] P. Zhou, G. M. Brown, and B. Gu, ‘Membrane and Other Treatment Technologies — Pros and Cons’, in Perchlorate: Environmental Occurrence, Interactions and Treatment, B. Gu and J. D. Coates, Eds. Boston, MA: Springer US, 2006, pp. 389–404.

[7] ‘Membrane Filtration’, Water Quality Products. [Online]. Available: https://www.wqpmag.com/membrane-filtration. [Accessed: 27-Oct-2018].

[8] J. Nemeth-Harn, ‘What is Membrane Water Treatment Technology and Why Do We Specialize In It?’ [Online]. Available: http://blog.harnrosystems.com/what-is-membrane-water-treatment-technology-and-why-do-we-specialize-in-it. [Accessed: 27-Oct-2018].

[9] A. the A. P. Manison, ‘Sustainable membranes for wastewater applications’, Water Technology, 01-May-2013. [Online]. Available: https://www.watertechonline.com/sustainable-membranes-for-wastewater-applications/. [Accessed: 27-Oct-2018].