What if we told you that your sewage is now worth big bucks and we cannot afford to just flush it? Of course, water is quite valuable, but what about all that wealth in your dump that’s going to waste?

Surely you have heard about landfills being the mines of the future, given the number of valuable materials that could be recovered from them, especially when it comes to e-waste and precious metals. In the same manner, there is also another resource of equal potential kept in the shadow until now: wastewater.

Undervalued wastewater from domestic, agricultural, and industrial activities can also be thought of as a mine of valuable components instead of something to get rid of. Taking advantage of that potential means that we could partly cover the demand of raw materials coming from fresh resources, thus minimizing our dependence on limited stocks.

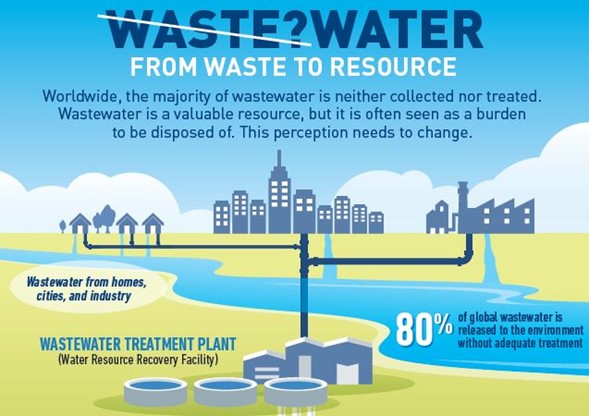

As shown by Figure 1, about 80% of wastewater is released to nature without adequate treatment, which apart from being completely detrimental to the environment, leads to wasting many valuable components. But, would this figure be different if only we realized the value of the multiple resources contained in wastewater?

Figure 1: The necessity for a shift of paradigms around wastewater

By closing loops through this system, most of the consequences circle the improvement of systems sustainability, framed by reduced energy and water inputs while attaining production costs reduction and less waste production.

As the first step for this transition, wastewater treatment facilities must be converted into waste resource recovery facilities. This way, we would be able to close loops around water and other materials simultaneously.

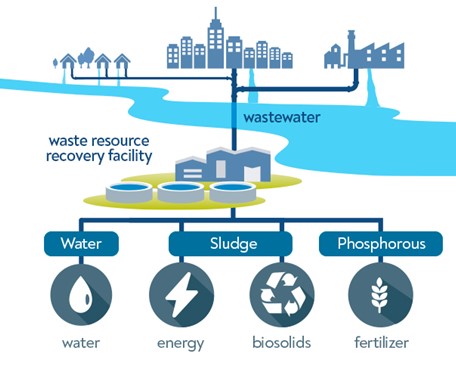

Figure 2 gives a hint of the possibilities. Besides water recovery and revalorization, the alternatives are as diverse as the processes producing the effluent. Depending on the origin, wastewater can carry nutrients and chemicals, and energy sources.

Figure 2: Transformation of wastewater treatment plants into resource recovery facilities[1]

One of the most important residual sources of nutrients is urine. Abundant in domestic water effluents, urine is rich in nitrogen, phosphorous, potassium, and sulfur, and Cl-, magnesium, and copper to a lesser extent.

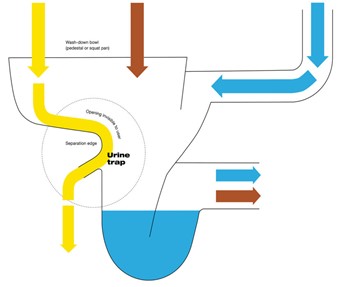

But to harness its utter potential, urine must be separated from sewage at the source, given that the mixing lowers its valuable quality as a source of nutrients[2]. So, solutions like that shown in Figure 3 can be implemented to keep this potential untouched.

Figure 3: Novel design toilets that allow to separate urine at the source

The organic matter contained in wastewater can be submitted to anaerobic digestion to produce biogas. Upgraded biogas can substitute that of fossil origin to be used in mobility, for heat, in power cycles to produce electricity, or as commodity chemical.

But anaerobic digestion is also useful to treat high strength wastewater since it allows to reduce the production of sludge during treatment with methane as a by-product[3].

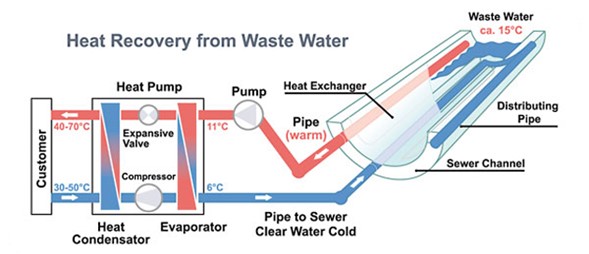

But wastewater can also be used as a source of sustainable heat. This technique is known as Riothermia and a Figure 4 shows what it is about.

Figure 4: Riothermia turns wastewater into a sustainable source of heat

Swedish studies showed the potential of Riothermia for heat production. In northern areas, it is capable of generating around 720 GWh of energy savings per year[4]. This amount of energy can cover the space heating needs of around 458 Belgian households or 703 average European households in one year[5].

High-tech has boosted the demand for metals and precious metals, bringing some economies up to the rise around the world. Thanks to technological advances and these elements we can now drive electric cars, have powerful phones in our hands, and work on impressive computers.

But with that comes a price, mining activities generate great environmental impacts around the world polluting rivers with mercury, arsenic, and other hazardous substances. Yet, metals and precious metals can be recovered from wastewater right at the point of discharge of the processes that generate them as waste.

Electroplating, batteries manufacturers, or mining activities themselves could revalorize their effluents by implementing the right management strategies and techniques. This way, zinc, nickel, iron, chromium, cadmium, lithium, and precious metals like gold, silver, and different rare elements are kept where needed and away from our aquifers and soils.

The pharmaceutical industry is also a user of different minerals. Zinc, for example, is used as an oxide for the production of creams, ointments, and other cosmetics, but it is also used in the formulation of insulin-regulating compounds.

Despite being regulated by strict standards for obvious reasons, the pharmaceutical industry is slowly taking steps towards the adoption of circular management strategies. Reclamation of solvents, zinc, and water is permitted, although still with many limitations, either technological or regulatory. Even so, some of the largest companies are implementing advanced technologies that allow them to revalorize as many components of their cycles as possible.

We bet on technology to keep its momentum on demonstrating the vast possibilities for recovery of high-quality materials that can be safely reused as commodities within the pharmaceutical industry.

We count on all the means to go beyond the status quo of economic growth and take a step further by transforming our systems. If we realize the economic potential hidden in waste streams, it is possible to untie economic growth from the need for virgin feed to keep advancing as a society. Second-hand commodities give us the chance to keep the technological pace going, but with more intelligent and efficient use of the existing resources.

Water experts can provide independent advice, guidance, and adequate technology to achieve circular water management within your system. We carry full water audits to optimize water use and become more water-efficient.

[1] D. Rodriguez, H. Serrano, A. Delgado, D. Nolasco, and G. Saltiel, ‘From Waste to Resource: Shifting paradigms for smarter wastewater interventions in Latin America and the Caribbean’, Washington, DC, 2020.

[2] E.-L. Viskari, G. Grobler, K. Karimäki, A. Gorbatova, R. Vilpas, and S. Lehtoranta, ‘Nitrogen Recovery With Source Separation of Human Urine—Preliminary Results of Its Fertiliser Potential and Use in Agriculture’, Front. Sustain. Food Syst., vol. 2, 2018, doi: 10.3389/fsufs.2018.00032.

[3] P. E. Poh, D. Gouwanda, Y. Mohan, A. A. Gopalai, and H. M. Tan, ‘Optimization of Wastewater Anaerobic Digestion Using Mechanistic and Meta-heuristic Methods: Current Limitations and Future Opportunities’, Water Conserv. Sci. Eng., vol. 1, no. 1, pp. 1–20, Jun. 2016, doi: 10.1007/s41101-016-0001-3.

[4] L. Mikkonen, J. Rämö, R. Keiski, and E. Pongrácz, ‘Heat recovery from wastewater: Assessing the potential in northern areas’, Aug. 2013, doi: 10.13140/2.1.1728.8326.

[5] ‘Heating consumption per m2 | Heating energy consumption | ODYSSEE-MURE’. https://www.odyssee-mure.eu/publications/efficiency-by-sector/households/heating-consumption-per-m2.html (accessed Apr. 27, 2021).